NO LARGE PROJECT’S EVER TOO BIG FOR US

What most amazes you about 3D printing? Could it be the 3D printed houses that are destined for the Netherlands? The fact NASA are using it to explore the impact of ice formations on aircraft wings or the fact it could possibly be used to help rebuild coral reef? For 3D printing and scanning, objects can’t be too large or too small.

We’re living, breathing and delivering this amazingness every day. It never ceases to amaze us just how truly ground-breaking the profession, our profession, is.

One thing’s for sure, it doesn’t discriminate. Needle eye-sized or football pitch scale, rhino horn, D-Day sculpture, car body or burger (yes, burger), the wonder of 3D printing is transforming the world with every new 3D print that’s produced. And what’s even better is that its impact is being felt sector-wide, from aerospace and automotive, to education and energy, the full force of 3D printing is transforming industry-upon-industry.

Let’s Talk Large- Scale 3D Printing….

But forget the intricacies and the teeny-tiny projects as small as a tooth. Some even smaller than that. We want to spend a few minutes focusing on the big stuff; the projects that are literally larger than life.

The parts we make are not limited by the build volumes of the printers. By bonding parts together we are able to make extremely large parts without sacrificing part strength.

If you’ve worked with us before or are aware of our expertise, then you’ll know that a lot of our time is spent 3D printing & 3D Scanning. We spend it within our temperature-controlled unit at our site in Bromsgrove, Worcestershire. For more details, check out this article.

…the 3D scanning projects that are so large we have to go off-site

But not all of our time is spent on-site. We very often take our 3D scanning skills off-site, particularly when we’re capturing larger projects that are simply far too big to take back to our base.

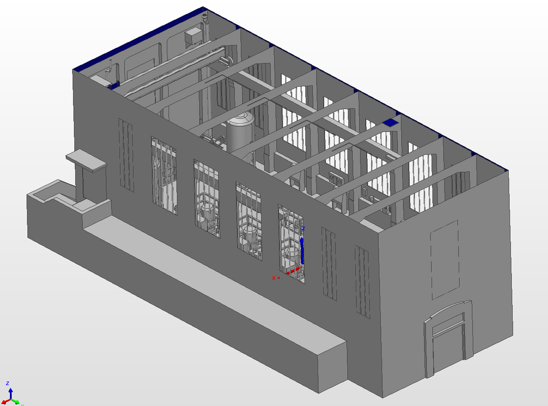

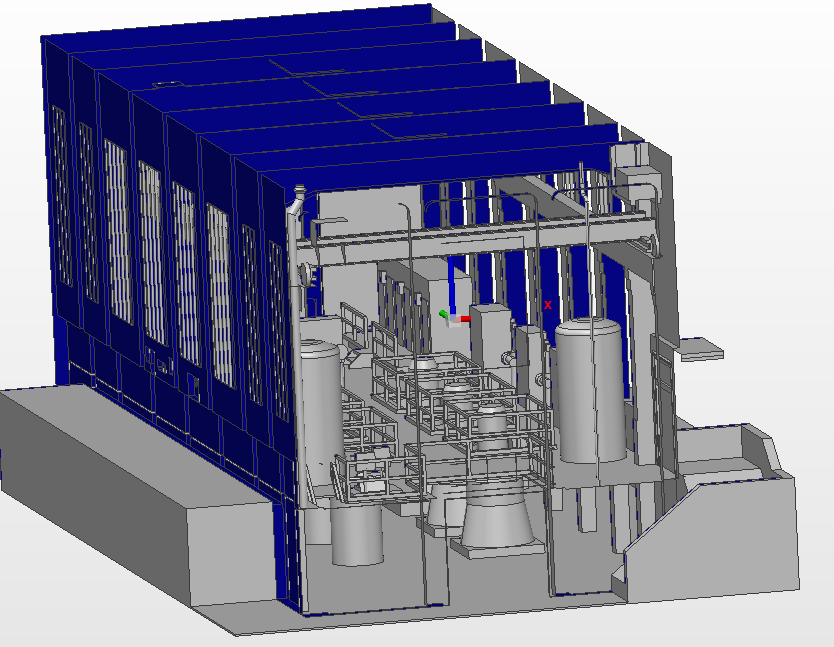

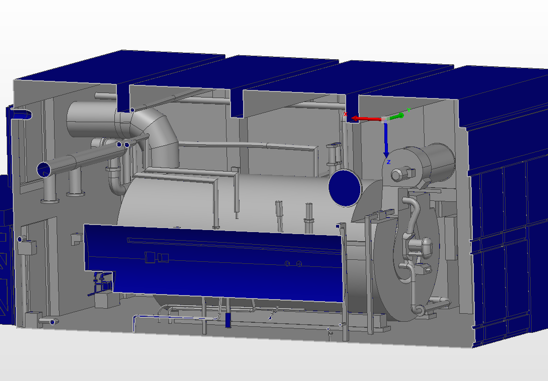

For instance, plant rooms and boiler rooms, or brownfield sites, as we like to call them. We’re often asked to capture them to provide our clients with a clear view of exactly what’s within the space, i.e. every hidden pipe, wires, hidden capacity. Having this clarity enables them to know what they can and can’t change. In addition, if they ever want to clear the spaces, it tells them in advance exactly how much room they’ve got to work with. Without being caught out by any unforeseen surprises.

Like These..

These scans were carried out using the Artec Ray 3D scanner. This is our largest 3D scanner of choice because of the laser dot technology and excellent software for data alignment. From a client perspective, this means we carry out our work quickly (we can easily capture 100 square metres in a day). As well as, cover everything (right down to the smallest detail), and all with unfaltering accuracy.

While most people think larger doesn’t necessarily mean as much detail as the smaller projects, they’d be wrong. We apply the same pinpoint accuracy and razor-sharp attention to detail to all pieces, large or small. This is thanks to the industry-leading equipment we use.

3D Printing And Scanning Large Objects

Got any questions or perhaps you have a large 3D printing project you’d like to discuss with us? No large 3D printing and 3D scanning project job is too big – or too small – for us. You can reach us on 01527 558282 or info@central-scanning.co.uk